DBS Village Expansion

Camp expansion designed to increase the accommodation capacity from 300 to 415 rooms to support the growing workforce at Newmont Tanami Operations.

Tailings Pipeline

The Tailings Pipeline Installation at the Granites Process Plant, part of the Tanami Expansion 2 (TE2) project, is a vital infrastructure development designed to enhance the tailings management capabilities of Newmont Tanami Operations.

DBS Village

Located 600km NW of Alice Springs, DBS Village is built to accommodate 300 employees and provide them with a high standard of remote living.

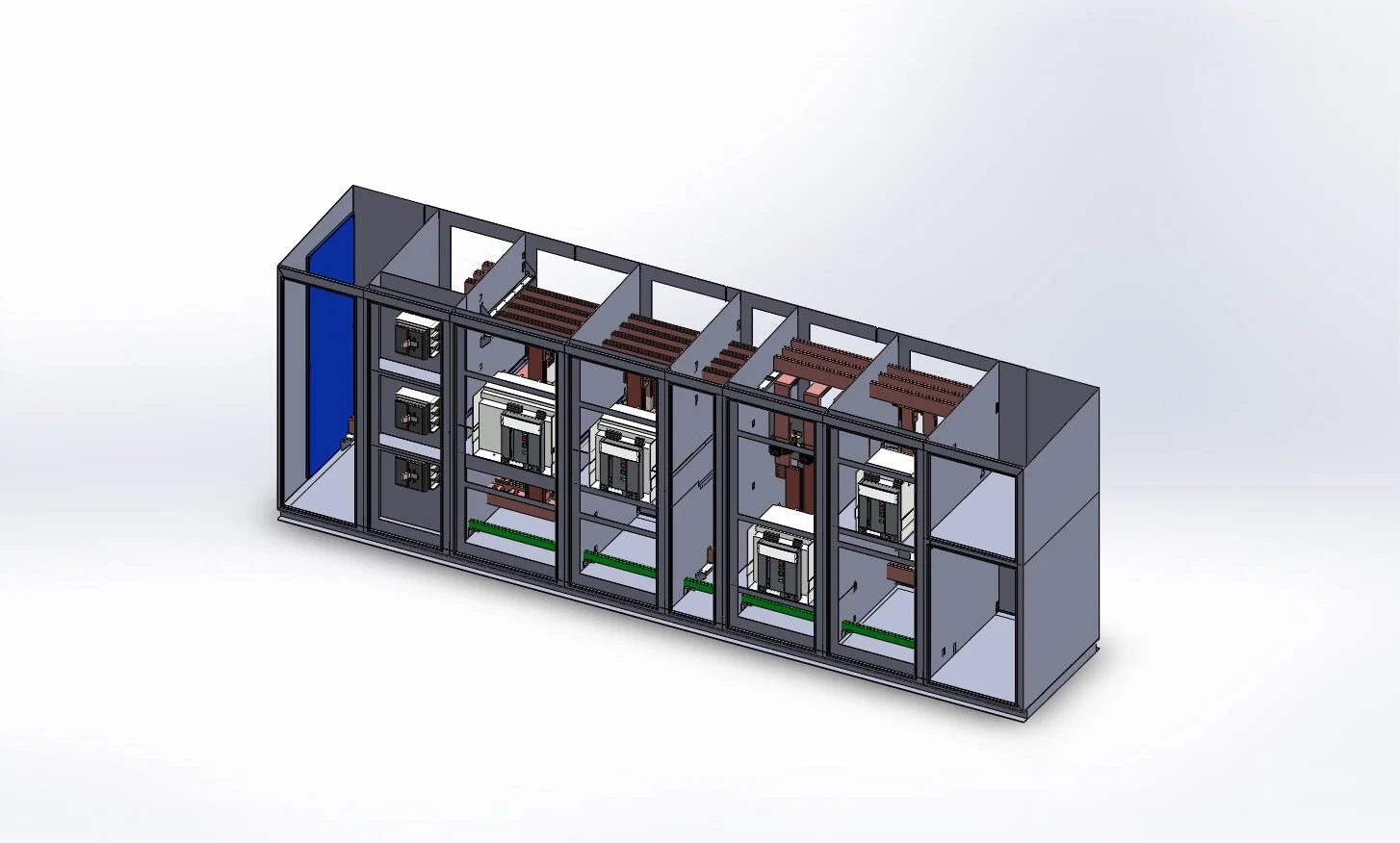

Nauru Mains Power Upgrade

HTS provided design, procurement and installation support for the upgrade of local electrical infrastructure

Refurbishment of Modular Buildings

This project involved the refurbishment of modular buildings in Yatala, QLD and the transportation of over 150 buildings to central Australia.

CBH Stage 1 - Install of New Accommodation and Facilities

HTS mobilised to seven CBH sites to install accommodation and facilities